First-class reworking solutions from gKteso

- Improving the quality of cast components

- Reliable machining of complex geometries

- Increasing throughput and optimizing efficiency

Finishing of cast components

First-class reworking solutions from gKteso

- Improving the quality of cast components

- Reliable machining of complex geometries

- Increasing throughput and optimizing efficiency

Finishing Cast Components and Save Time and Money

Fully Automatic, Multi-Axis Finishing Machines Deliver Perfect Results

Cast components almost always form sharp-edged burrs at the separating edges which have to be removed at great expense after the material has solidified. Manual deburring is time-consuming and expensive. Many companies therefore outsource this step of the process to external service providers – resulting in cumbersome transport logistics and longer processing times. But the finishing of cast components can also be carried out easily and fully automatically in your own company. gKteso’s automated systems ensure high machining quality, significantly increase piece counts compared to manual machining, and integrate seamlessly into any production routine.

The fully automatic, multi-axis deburring cells deliver the best results and can be used both as stand-alone systems and as part of a production line. Cast components can easily be finished directly after cooling.

- Cast iron

- Zinc die casting

- Cast aluminum

- Aluminum die casting

- Cast steel

- Cast brass

- Cast bronze

- Plastic injection molding

Automatic deburring of

- Cast iron

- Zinc die casting

- Cast aluminum

- Aluminum die casting

- Cast steel

- Cast brass

- Cast bronze

- Plastic injection molding

Automated finishing of workpieces and complete machining of cast components

- Ensure dimensional accuracy

- Optimize surfaces

- Improve quality

Increasing Throughput and Optimizing Efficiency

Do you have questions about the technology solutions from gKteso for the cast components industry for machining cast parts? Then call us or write to us.

+49 8234 966 38 41

- 28 years of experience

- Simple, fast and inexpensive

- Sophisticated modular system

Do you want to know more about the finishing of cast components with machines from gKteso?

We look forward to receiving your inquiry!

DS base Deburring System – Finishing Cast Components Automatically

Automated Reworking of Cast Components

Cast components can be finished to size using gKteso’s deburring and grinding systems. The result is precision-fit components without problematic burrs and edges, fraying or splinters. The fully automatic deburring cells operate in multiple axes and can also comprehensively detect complex component geometries. With the entry-level DS base model, cast components made of different materials and for different industries are finished. Precise and clean surfaces are produced even at high machining speeds.

The DS base grinds or mills edges automatically. Depending on the basic material of the cast components, light milling and drilling work, thread cutting or 3D trimming are also possible. The system can be tool-guided or workpiece-guided – with a workpiece-guided system, cycle times are shorter and throughput is higher.

Advantages:

- 5 or 6-sided machining

- High throughput

- Repeatability 0.05 millimeter

- Milling, brushing, marking – all in one machine

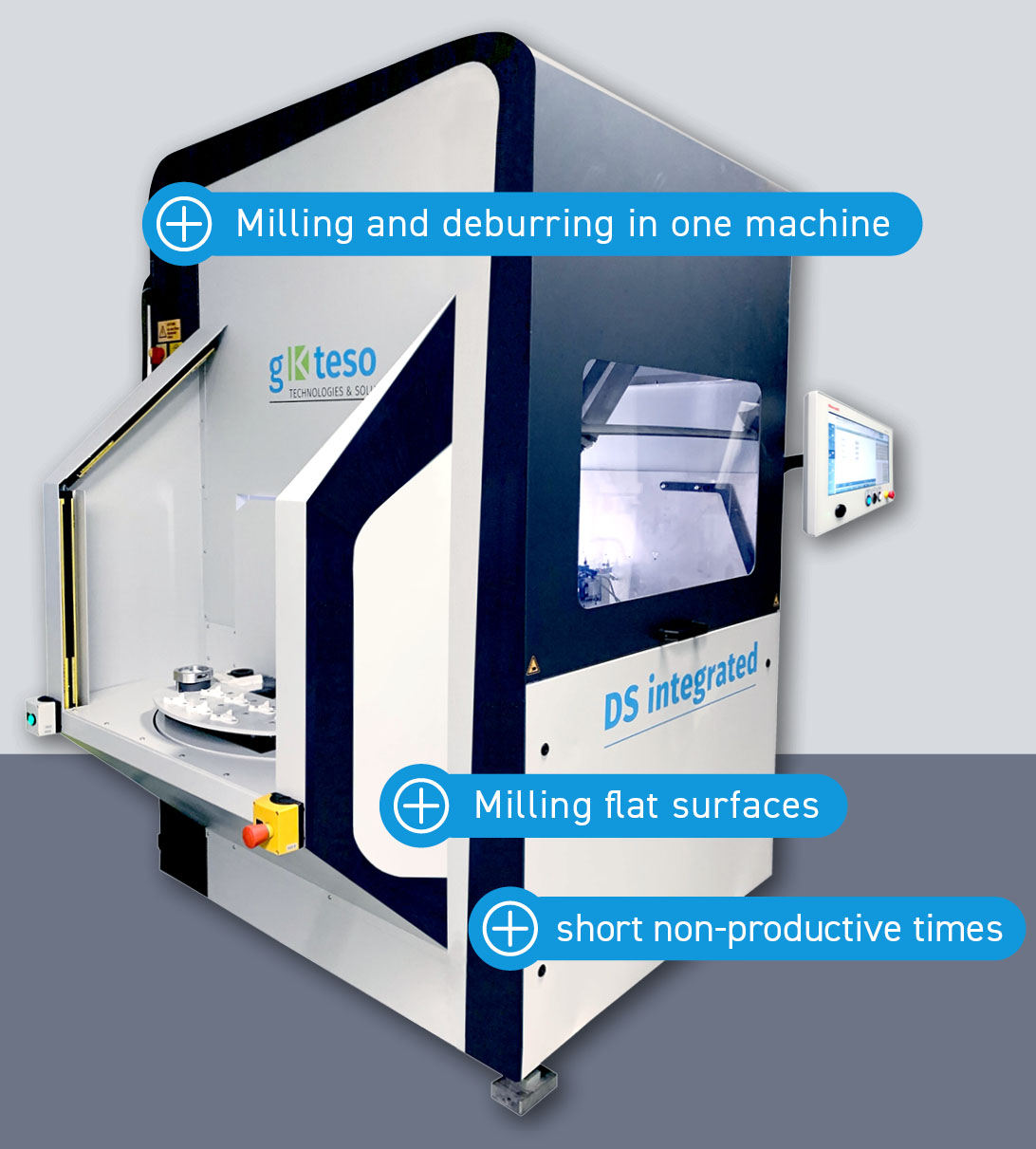

DS integrated Deburring System – the Fully Automatic Deburring Cell for Cast Components

Save Time, Money and Effort Thanks to the Shuttle or Rotary Table

In addition to the entry-level DS base model, gKteso has developed the DS integrated deburring system. The main difference is in feeding the parts: The DS integrated offers a shuttle or rotary table for this purpose. The advantage: Machining inside the deburring unit does not have to be interrupted during loading.

The work area of the DS integrated is spacious at 500 x 500 x 300 millimeters and offers room for machining numerous different cast components.

Advantages:

- Conserves resources

- Milling, thread cutting

- Brush + deburring

- 5-axis technology

- Includes shuttle table or rotary table

Milling

Mill cast components and produce flat surfaces, machine separating edges or remove problematic burrs. For cast components made of steel as well as aluminum and zinc die casting.

Drilling & Thread Cutting

Machine cast components and subsequently drill holes or cut threads. Finishing machines for perfect components as required.

Deburring

Deburr cast components and shape them using various tools depending on the nature of the component.

Grinding

The surface of cast components can be significantly improved by grinding, prepared for coatings or corrected in shape.

Marking & Checking

The quality of cast components can be significantly improved by scanning with the laser or scanning with the 3D probe – define targets and have them checked automatically.

Mill cast components

with gKteso

Milling

Cast components are used in a wide variety of applications and are installed, for example, as housing parts, and serve as fixtures or fittings. With the automated milling machines for cast components, aluminum cast components can be milled or zinc die casting can be machined.

- Mill complex free-form surfaces

- Finish cast components

- Apply functional surfaces

Drill cast components

with gKteso

Drill & cut threads

Precise drilling and thread cutting

Ensure variant diversity and optimize cast components

Cast components usually require finishing operations to prepare them for their subsequent use. Sometimes holes or frictions are missing, for example for the maximum fitting accuracy of pins in fixture components. Or the cast component has only conical pilot holes due to the manufacturing process, which have to be re-drilled. Milling machines for cast components can be used to optimize housings for electronic parts as well as cast fittings, cast aluminum parts or zinc die castings.

- Introduce frictions

- Thread cutting

- Drill missing holes

Deburr cast components

with gKteso

Deburring

The gKteso finishing machines are extremely flexible.

Depending on the desired work step, the tool and spindles are matched to the components. Inaccurate edges of cast components can be deburred with flexible, deflectable spindles for optimum results. Defined edges, on the other hand, are reliably machined with fixed spindles. Bores of cast components can be cleanly deburred with the reverse deburrer.

- Deburr cast components as required

- Interchangeable tools

- Select suitable spindles

Grind cast components

with gKteso

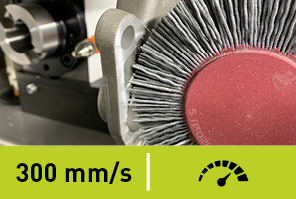

Grinding

Regrinding and sharpening

Cast component machining often requires shape corrections or preparation for coatings

Cast component grinding is particularly important to remove interfering separating edges or to prepare the components for further processing at a later stage. The grinding of cast components is part of the finishing process and aims to optimize their quality. On the one hand, grinding improves the shape, while on the other, the texture of the surface can be changed.

Coatings adhere much better and more homogeneously to a pre-ground surface than to the un-machined surface of the cast component. Traces of manufacture, such as separation seams, can also be ground out in the finishing system.

- Prepare coatings

- Ensure form fidelity

- Remove manufacturing residues

Mark cast components

with gKteso

Mark and check

Improve quality through testing and component identification

Laser scanner and 3D probe reliably check the fit

It must be possible to clearly assign components in the production process. To ensure that this succeeds at all times, cast components can be permanently marked using various processes. In the process, the cast components are either imprinted or laser-marked as required. Engraving is also suitable for cast components, for example with the component number, the production date or an identification code.

The final quality check can be done fully automatically in the finishing machine – this is much more efficient and accurate than the previous visual inspection. For this purpose, cast components are inspected according to specified dimensions using a laser scanner or 3D probe. Which tolerances are allowed can be set individually.

- Reliably scan cast components

- Check dimensions with the 3D probe

- Reliably mark cast components